MULTIPHASE PORFEED POWER SUPPLY

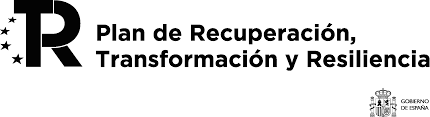

Ecosystem and Prosystem are two automatic multiphase dry feeding systems for managing, elaborating and distributing recipes for pig weaning.

The main objective is to offer a gradual feed transition, mixing different types of feed, of different composition, to improve adaptation and reduce digestive problems. In this way, the piglet adapts to solid feed and is supplied with all the necessary nutrients according to its body composition, optimizing its growth.

MAIN FUNCTIONS

Operational highlights

TOTAL MANAGEMENT

Design of feed curves and choice of feed type by zones.

CONTROL AND WARNINGS

System equipped with multiple sensors that warn in case of failure or breakdown.

CONSUMPTION REGISTER

The program stores all the data to provide a record of consumption and to easily calculate production costs.

PROSYSTEM

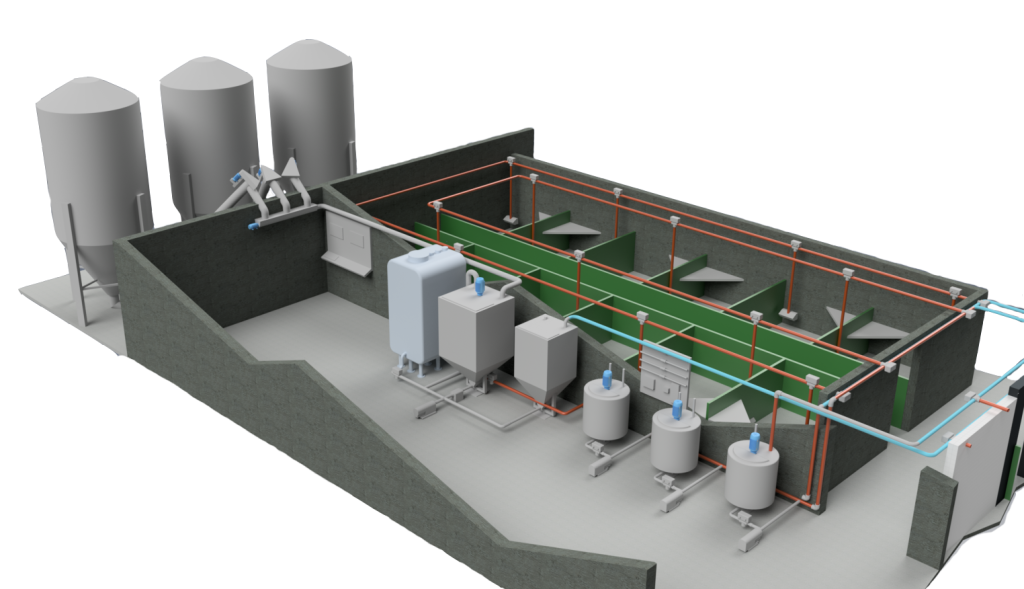

Automated feeding with weighing

The ProSystem offers the possibility to prepare recipes with a precise percentage of each feed and then mix it in a 100kg capacity tank.

The control is done with a PLC or a computer

. The recipe components are evolved by weight inside the mixing tank, then mixed to achieve a homogeneous result, passed to a diverter tank and distributed through the desired circuit.

As soon as the reservoir is emptied and the mixture starts to be distributed, the next recipe is prepared to optimize preparation times. A capacitive detector takes constant readings to verify that the feed passes through the corresponding valve and that the recipe is evacuated at the required point.

In addition, it is also used as confirmation of feed passage, to avoid mixing of two recipes in the line. These procedures are repeated until all feeders are supplied with feed.

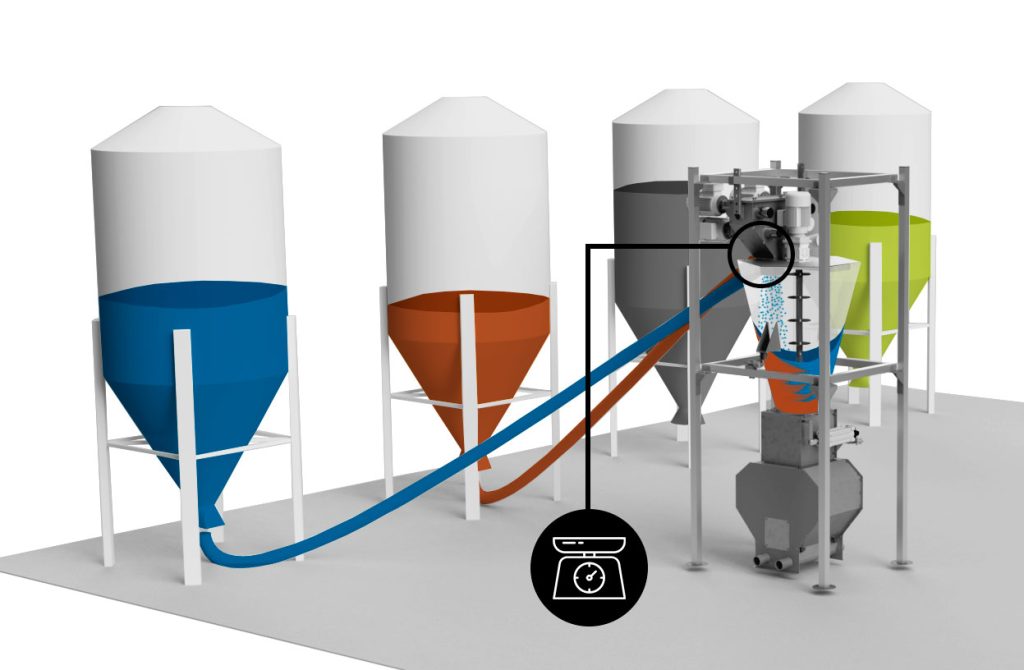

ECOSYSTEM

Automated speed feeding

The Ecosystem works with volumetric control. It is sufficient to indicate the volume of each component only once.

It offers the possibility of

to prepare an individual feed recipe for each valve. This system

does not require a mixer, distribution units or feed kitchen.

It is an economical system and especially suitable for large herds.

The control is done with a PLC or a computer.

The dosing of the different feed components is done

directly to the tube conveyor. An automatic loading unit

auger with variable speed, under the silo, allows to control the

feed volume according to the composition of each recipe.

Advantages for the piglet

> Reduced digestive problems

> Increased weight gain in piglets

> Easy start to weaning

> Increased adaptation to solid feed

> Ensures intake of all nutrients > Increased adaptation to solid feed > Increased weight gain in piglets > Increased adaptation to solid feed > Guarantees the intake of all nutrients

Advantages for the professional

> Reading of consumption and total costs per batch

> Saving of handling time

> Easy management

> Good conversion

> Total control of the operation

> Adaptable to any type of feeder

> Low operating cost

> The operating system can be executed from the PLC located

in the electrical cabinet, or remotely through

from a computer or cell phone.

MAIN COMPONENTS

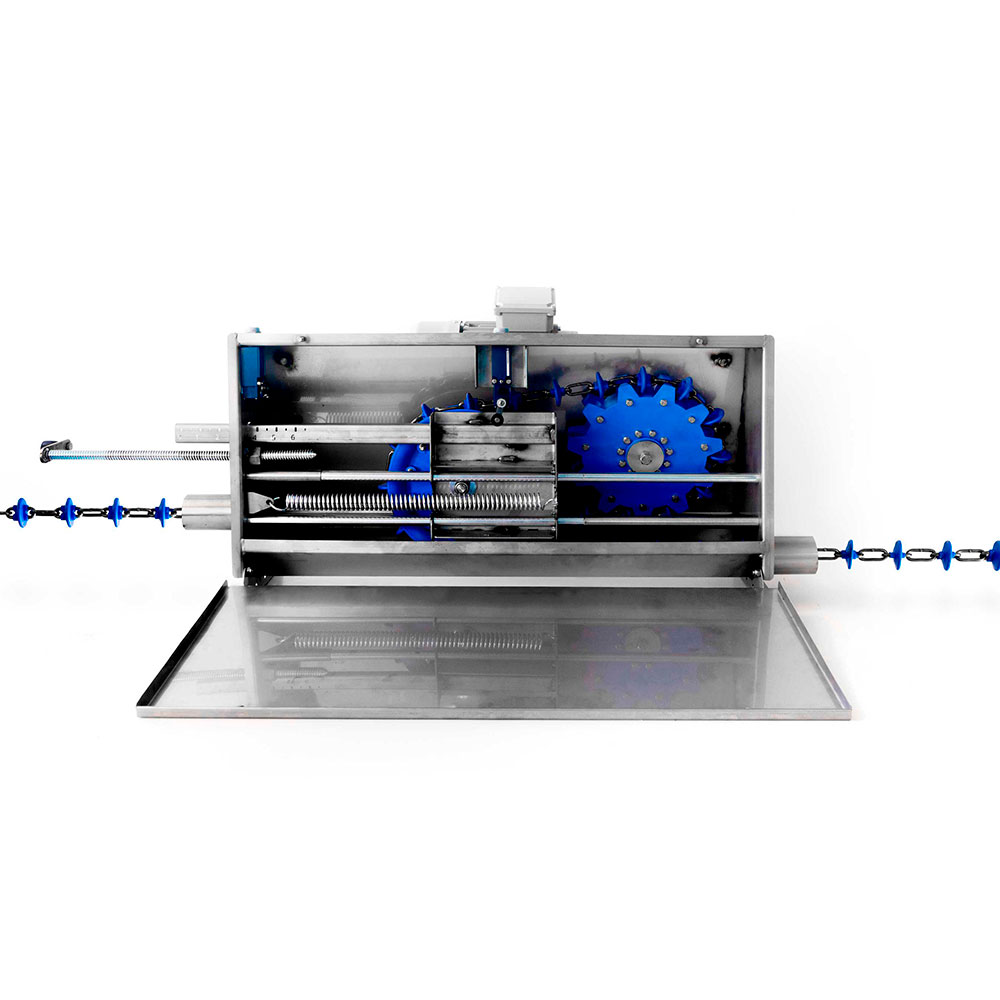

UNIT

OF DRAWING

' Automatic system

' Chain tensioning mechanism

' Efficient and consistent feed distribution

' Reduction of feed losses

' For tube Ø60mm

UNIT LOAD

AUTOMATIC ENDLESS

' Feed drop regulation

' Controlled feed distribution

' Reduction of feed losses

' For tube of Ø60mm

' Requires electrical connection

VALVE

T-FEED

' Pneumatic opening mechanism

' Connection with tube Ø60mm

' Downspout Ø70mm

' Entirely made of stainless steel

SENSOR OF

CHAIN

' Constant reading of the feed rate

' Easy installation at any point of the line

' Reliability of reading

' Dual utility

CORNER

90º

Stainless steel 304 construction

' Inlet for tube of Ø60mm

' 90º rotation

' All elements included

' Easy installation

GRAPA

With rubber to improve watertightness

' Manufacture in stainless steel 304

' Support of two equal parts

' Fastening with 6 M8 screws

' Easy installation

CHAIN

Stainless steel 304 construction

' Injected blue polypropylene discs

' Durability and resistance

' Custom lengths

SUPPORTS

' Vertical and horizontal supports

' Customizable and adaptable to each installation

' Adjustable positioning of tube ' Adjustable

' Durable and robust

' Made of stainless steel